Pneumatics is often a branch of mechanical engineering that deals while using use of air pressure in creating motion or some kind of mechanical force. Pneumatics can be used mainly in factories and industries where compressed air is dealt with. The compressed air or steam is stored in a single location and distributed through valves. Compressed gases are a more affordable means to fix using electric motors and actuators. Pneumatics is used because in the cheap option of air. Air costs nothing. Compressed air may be stored and used even when electrical power is lost. The design is basic and straightforward, utilizing existing components like cylinders and pistons.

The first pneumatic tool probably was the bellows used by blacksmiths. Modern air compressors were designed within the 1800s and were used in department stores. The system was utilized between sections to get change. Air compressors were also utilized on barges and boats. These were hand operated and needed four hardy men to maintain it going. The air pump was employed to supply air to divers. Due towards the limits of human strength high pressures could not be produced and this limited the depth the divers could go to. As steam engines began being used, the man power was replaced by this.

Air compressors began to become used extensively within the second half from the 19th century. Compressed air was utilized to dig the foundations with the Brooklyn Bridge. The silt underneath the river was very porous as well as the water kept seeping in the caissons. Compressed air was utilized to keep out your water. Pneumatic machines gained popularity fast and industrial installations all throughout the country started using them. There were uncertainties on whether steam or electricity was the vitality with the future. In the conclusion electricity won out because small businesses can't afford steam systems.

The device that converts power into kinetic energy through the way of air compression, which when demanded can release great air bursts is referred to as air compressor. The power is usually derived coming from a diesel engine, electric motor, or gasoline engine. Air compressors are popular and used in several industries for safe, neat and convenient usage of air. The types of air compressors could be classified about the basis of either positive displacement or negative-displacement. They are as follows:

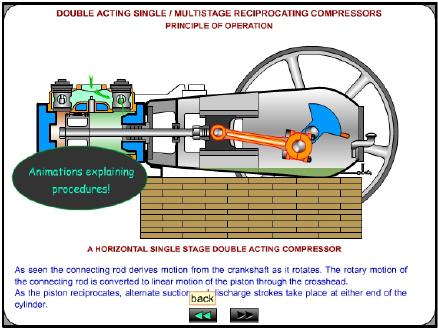

• Reciprocating or Piston Compressors: These include the most common ones with positive displacement compressing unit. The powers change from fractional to extremely high. The air is filled inside chamber after which volume from the chamber is reduced, thereby creating compression and thus releasing the energy. The inner components include valves, cylinders, crankshafts, pistons, and housing blocks.

• Centrifugal Compressors: Not an optimistic displacement compressor, this uses high speed spinning impellers and accelerates mid-air after which use the diffuser to destroy the air. This air compressor uses the method of dynamic compression whereby velocity is employed to increase pressure. Centrifugal compressors have numerous impeller/diffuser combinations as well as inter coolers to cool mid-air relating to the stages.

- Motor Type: 5HP Or 5.5HP/4kw

- Speed: 1250RPM / Air Delivery: 18.8 CFM

- Rated Air Pressure: 115PSI /Max Air Pressure: 155PSI / Capacity: 560L/Min

- Air Delivery @ 655RPM - 12.1 SCFM @ 40 PSI - 11.5 SCFM @ 90 PSI

- Air Delivery @ 1050RPM - 17.5 SCFM @ 40 PSI - 15.2 SCFM @ 90 PSI

How to Maintain your Air Compressor to own longer and healthier

Any Machine is worth as long as it functions properly, compressors are not any exception to the rule; we are able to put them to effective use when we these are maintained and held in good working condition.

In this informative article we'll highlight some basic but effective tools to keep your compressor well-maintained to ensure they perform their job most diligently for a long time to come. The most simple and easy foremost advise would be ensuring which you drain water from your compressor every time you bring it to use. You will often look for a valve more typically on bottom side of your compressor that will assist you to easily drain the water. If followed regularly this process won't allow the water to accumulate in the tank and protect the machine body from any rust formation on its inner surface. Not only this if water level goes beyond a certain limit within the compressor tank, it won't leave enough room for air to pass through hence resulting in pressure loss.

- Max. Air Pressure: 140 PSI / Max Air Delivery: 10.8 CFM

- Speed: 1,000rpm (50Hz/60Hz)

- Max Pressure: 8 Bar @ 115PSI

- Fly Wheel: 11" (Included)

- Four 7/16" Mounting Holes (1/2" X 14 TPI)

American standard heat pumps really are a must have. This company offers heating devices with efficiencies of around 9 HSPF or Heating Seasonal Performance Factor and 17.7 SEER for air conditioning.

They also offer Acculink Communication system that may allow you to change settings remotely and allows different components to convey to each other. This is advantageous since this allows the compressor to watch the indoor blower as well as the condenser fan motor. Thus, if the indoor blower and the condenser fan motor usually are not running then the compressor may also know that it cannot run. This can be a good protection system for your owner.

American standard heat pumps are definitely an incredible value as they are some from the most well built and economical heating and cooling units being manufactured today. This company has been making good quality heating and cooling devices for a good time. So company is ensured of the quality of the product that they are buying.

Compare Prices Campbell Hausfeld VT6271 26 Gallon ASME Oil-Lubricated 240V Horizontal Air Compressor

- Heavy duty CAST IRON oil lubricated twin cylinder pump

- Powers a variety of air tools for the serious do it yourselfer or contractor

- Product life of up to 5000 hours based on b-10 bearing rating

- High horsepower motor capable of running on 240 volts

- Durable and safe ASME code tank for greater air storage, 3 year warranty

Categories

- 115208230Volt (1)

- 115230 (1)

- 120Volt (1)

- 1250RPM (1)

- 12Volt (2)

- 148CFM (1)

- 155PSI (1)

- 166Amp (1)

- 16Gallon (2)

- 1Gallon (1)

- 200PSI (1)

- 230Volt (1)

- 27Gallon (1)

- 2Gallon (1)

- 2Horsepower (1)

- 3450rpm (3)

- 412Gallon (1)

- 4Gallon (2)

- 55Horsepower (1)

- 5Horsepower (1)

- 5HP55HP (1)

- 60Gallon (2)

- 80Gallon (1)

- 843001W (1)

- 8Piece (1)

- Accessories (1)

- Accessory (1)

- AF321 (1)

- Aluminum (1)

- American (2)

- Applications (2)

- Bearing (1)

- Between (1)

- Business (1)

- Buying (1)

- California (5)

- Campbell (2)

- CAT116DLH (1)

- CAT1675A (1)

- Cfm175 (1)

- Cheap (4)

- Chemistry (1)

- Choice (1)

- Choosing (3)

- Compare (4)

- Components (1)

- Compressed (1)

- Compressor (53)

- Compressors (12)

- Condensing (1)

- Conditioner (1)

- Conditioning (1)

- Consider (1)

- Contractor (1)

- Control (1)

- Convert (1)

- Cooler (1)

- CTA5090412 (1)

- CYLINDER (5)

- Cylinders (1)

- D55001 (1)

- D55140 (1)

- D55146 (1)

- D55168 (1)

- Deal (2)

- Description (1)

- DeVilBiss (1)

- DEWALT (4)

- Difference (1)

- Direct (2)

- Discount (3)

- Displacement (1)

- Driven (1)

- Dynamic (1)

- EC2510E (1)

- Electric (3)

- Electric246 (1)

- Energy (1)

- Engine (1)

- Explained (2)

- FC1500HBP2 (1)

- Features (2)

- FP2048 (1)

- Frame (1)

- Gallon (4)

- Generator (1)

- Get (3)

- Goodman (2)

- Goodyear (1)

- Hausfeld (2)

- Heating (1)

- HeavyDuty (1)

- HiFlo (1)

- Highly (1)

- Hitachi (2)

- Horizontal (1)

- IL1982713 (1)

- ILA3606056 (1)

- Important (1)

- Industrial (4)

- Inflator (1)

- Ingersoll (1)

- Install (1)

- Intl (1)

- IV5248069 (1)

- Kaeser (1)

- MAC2400 (1)

- MAC5200 (1)

- MAC700 (1)

- Maintain (1)

- Makita (4)

- Medical (1)

- Motor (2)

- Motorpump (1)

- Motors (1)

- MP100220V (1)

- MP20022060 (1)

- NewAir (1)

- OffRoading (1)

- OilFree (7)

- OilLubricated (2)

- Operations (1)

- Pancake (1)

- Paragon (1)

- Picking (1)

- Pneumatic (1)

- Pneumatics (1)

- Pontoon (2)

- Popularity (1)

- Portable (4)

- PorterCable (1)

- Positive (1)

- Practical (1)

- Pressure (1)

- Prices (4)

- Product (2)

- PUMP (1)

- PumpMotor (4)

- Purchase (2)

- Purchasing (1)

- Quality (1)

- Reasons (2)

- Reciprocating (1)

- Related (1)

- Replacement (5)

- Review (1)

- Reviews (5)

- Rigid (1)

- RolAir (1)

- Selecting (1)

- Simple (1)

- Simplified (1)

- Single (3)

- Stage (2)

- Standard (2)

- SYCLONE (1)

- Synthetic (1)

- Systems (1)

- Take (1)

- Thats (1)

- Vacuum (1)

- Valves (1)

- Various (1)

- Vertical (1)

- VT6271 (1)

- VType (1)

- Weston (1)

- Wheeled (1)

- Wheels (1)

- Window (1)

- Without (1)

- Woodworking (1)

- Workshop (1)

- Youll (1)